RFID Technology |

RFID | Wireless | Mobility |

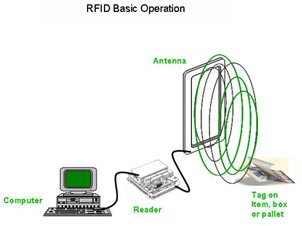

RFID is a general term that is used to describe a system that transmits the identity (in the form of a unique serial number) of an object wirelessly, using radio waves. This is sometimes referred to as contact-less technology and a typical RFID system is made up of three components: tags, readers and the host computer system.

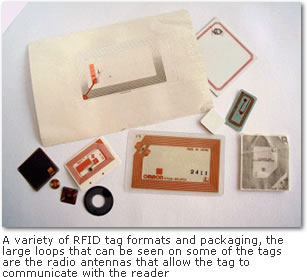

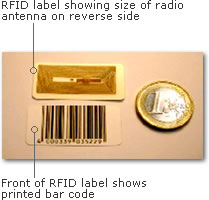

Tags - An RFID tag is a tiny radio device that is also referred to as a transponder, smart tag, smart label or radio barcode. The tag comprises of a simple silicon microchip (typically less than half a millimetre in size) attached to a small flat aerial and mounted on a substrate. The whole device can then be encapsulated in different materials (such as plastic) dependent upon its intended usage. The finished tag can be attached to an object, typically an item, box or pallet and read remotely to ascertain its identity, position or state.

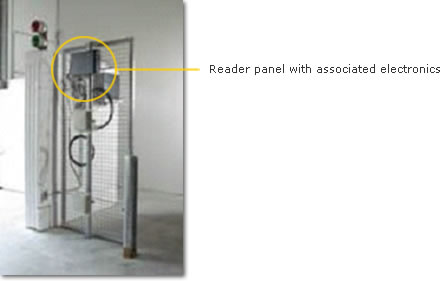

Readers – The reader, sometimes called an interrogator or scanner, sends and receives RF data to and from the tag via antennas. A reader may have multiple antennas that are responsible for sending and receiving radio waves.

Host Computer – The data acquired by the readers is then passed to a host computer, which may run specialist RFID software or middleware to filter the data and route it to the correct application, to be processed into useful information.

Automatic Identification

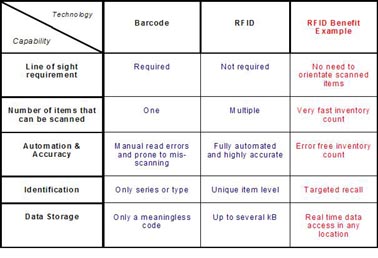

RFID technologies are grouped under the more generic Automatic Identification (Auto-ID) technologies. Examples of other Auto-ID technologies include Smartcards and Barcodes. RFID is often positioned as next generation barcoding because of its obvious advantages over barcodes. However, in many environments it is likely to co-exist with the barcode for a long time.

The barcode labels that triggered a revolution in identification systems back in the 1970’s are now cheap and commonly used, but have several limitations :

- low storage capacity

- they only represent a series of items and not an individual or unique item

- durability (as mostly printed paper)

- low read range

- they can only be read when line of sight is established

- they can only be read one at a time

- they cannot be written to or reprogrammed

Features and benefits of RFID over barcodes

Rather than using light to collect or read a number from a bar code, radio waves are used to read a number from the RFID tag. RFID therefore does not need line-of-sight to operate. Using radio means that the tag no longer has to be visible on the object to which it is attached; the tag can be hidden inside the item or box that is to be identified and still be read. This minimises or eliminates the need for a person to have to present the reader to the tag as it can now be fixed to a wall for example. As the item is passed by the reader it will be read automatically, thus giving a potentially large saving in labour costs or substantial increase in throughput of scanned items.

Another feature of RFID is the ability to read many tags together at once. It is not necessary to present each tag to the reader separately (as is required for barcodes), instead all tags within the range of the reader can be read almost simultaneously as they pass the reader. Again, there is a huge savings potential in not having to manually present the reader to each item to be identified.

Furthermore, data can also be written to the tag, a feature not possible with barcodes. This latter feature has tremendous implications for IT systems and the potential benefits of RFID.

Different Types of RFID

There are several versions of RFID that operate at different radio frequencies. The choice of frequency is dependent on the business requirements and read environment – it is not a technology where ‘one size fits all’ applications.

Three primary frequency bands are being used for RFID:

�� Low Frequency (125/134KHz) – Most commonly used for access control, animal tracking and asset tracking.

�� High -Frequency (13.56 MHz) – Used where medium data rate and read ranges up to about 1.5 meters are acceptable. This frequency also has the advantage of not being susceptible to interference from the presence of water or metals.

�� Ultra High-Frequency (850 MHz to 950 MHz) – offer the longest read ranges of up to approximately 3 meters and high reading speeds.

Applications for RFID within the supply chain can be found at multiple frequencies and different RFID solutions may be required to meet the varying needs of the marketplace.

Since UHF (Ultra High Frequency) has the range to cover portals and dock-doors it is gaining industry support as the choice frequency for inventory tracking applications including pallets and cases.

RFID tags are further broken down into two categories:

Active RFID Tags are battery powered. They broadcast a signal to the reader

and can transmit over the greatest distances (100+ meters). Typically they can cost £5 - £20 or more and are used to track high value goods like vehicles and large containers of goods. Shipboard containers are a good example of an active RFID tag application.

Passive RFID Tags do not contain a battery. Instead, they draw their power from the radio wave transmitted by the reader. The reader transmits a low power radio signal through its antenna to the tag, which in turn receives it through its own antenna to power the integrated circuit (chip). The tag will briefly converse with the reader for verification and the exchange of data. As a result, passive tags can transmit information over shorter distances (typically 3 meters or less) than active tags. They have a smaller memory capacity and are considerably lower in cost (less than £1) making them ideal for tracking lower cost items.

There are two basic types of chips available on RFID tags, Read-Only and Read-Write .

Read only chips are programmed with unique information stored on them during the manufacturing process – often referred to as a ‘number plate’ application. The information on read-only chips can not be changed.

With Read-Write chips , the user can add information to the tag or write over existing

information when the tag is within range of the reader. Read-Write chips are more expensive that Read Only chips. Applications for these may include field service maintenance or ‘item attendant data’ – where a maintenance record associated with a mechanical component is stored and updated on a tag attached to the component. Another method used is something called a "WORM" chip (Write Once Read Many). It can be written once and then becomes "Read Only" afterwards.

Applications for RFID

Applications fall into two principal categories: firstly, short range applications where the reader and tag must be in close proximity (such as in access control) and secondly, medium to long application, where the distance may be greater (such as reading across a distribution centre dock door). A sample of applications is shown below:

- Access control for people ; there are many areas where RFID tags are carried by people to allow them to gain access to facilities or services:

- Secure access to work place

- Safety access to dangerous/secure equipment

- Access to a computer or vehicle

- Access to travel on trains/buses

- Access to leisure facilities

- Access control for vehicles:

- Secure access on site

- Road tolling

- Instant payment for fuel

- Manufacturing automation:

- Control of flexible manufacturing processes by recognising items being built on a production line (mass customization enabler)

- Labeling key components for later recycling

- Logistics and distribution:

- Tracking parcels from shipment to end customer

- Tracking goods from manufacture through to retail

- Retail:

- Supply chain management

- Stock taking

- Reducing loss through shrinkage

- Reverse logistics

- Product availability

- Maintenance:

- Plant & Equipment

- Fixed assets

- Patients

- Product security:

- Tamper evidence

- Product authentication

- Anti-counterfeiting

RFID Technology | Standards | Business Benefits